PorterSIPS

Structural Insulated Panels are becoming more and more popular in the design and construction of green homes. Their amazing insulating properties help homeowners achieve significant reductions in the amount of energy necessary to heat and cool their homes.

Green Home Source often incorporates SIPs into our green home plans and renovations (like our Woodka Project.) The SIP product we recommend is the PorterSIP. Located in Holland, Michigan, PorterSIPS has been at the forefront of SIP design and manufacturing for decades; their state-of-the-art manufacturing facility uses a continually-improving process that results in the highest quality SIP product available in the marketplace.

Green Advantages of PorterSIPs

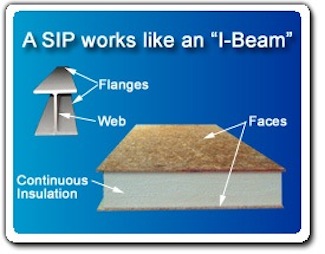

SIPs provide incredible energy-efficiency for homeowners. A home built with PorterSIPs use about 50% less energy to heat and cool than traditional stick-built homes with conventional insulation materials. These energy savings are achieved while at the same time providing a wall structure that is much stronger than traditional stud framing. So strong, in fact, that homes built with PorterSIPs can reduce insurance costs in locations that are frequently subjected to very high winds.The dense foam insulating core at the heart of the PorterSIP allows for continuous insulation with no gaps or leaks. Thermal bridging, which is often an issue with stud framing, is a major source of energy loss in the home. By eliminating the stick framing and creating a wall with far fewer joints, PorterSIP walls thermal bridging is eliminated, as are issues associated with traditional insulation materials such as gaps and compression, which significantly reduce their performance.

PorterSIPs create an air-tight indoor environment, which contributes to healthier indoor air. This allows for the intake of outside air to be controlled and filtered, as well as the efficient expulsion of stale indoor air. Drafts are reduced, temperatures are more consistent throughout the home, and noise from outdoors is dramatically lowered.

The tremendous energy savings that PorterSIPs provide have been used as part of an overall design to create net zero-energy homes around the country. They contribute up to 46 points in the LEED for Homes certification, more than any other green building product. PorterSIPs can also add up to 39 points in the LEED category for Major Renovations.

PorterSIPs: A Manufactured Green Product

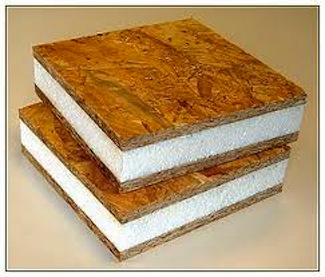

PorterSIPs create large energy savings in the home; their design and manufacture are green as well.PorterSIPs contain 89% engineered wood (OSB, 10% EPS foam plastic, and less than 1% water-activated polyurethane adhesives.

The OSB wood is sourced from managed forests containing small fast-growing trees, preserving old-growth forests. This wood is renewable, recyclable and biodegradable. Plus, the amount of wood used in walls built with PorterSIPs is approximately 85% less than a comparable wall built with traditional studs.

The OSB wood in PorterSIPs is formaldehyde-free.

The EPS foam that comprises the insulating core of the PorterSIP requires less energy (about 24% less) to produce than an R-value equivalent amount of fiberglass insulation. EPS foam does contain petroleum, a non-renewable resource, but the total amount is actually quite small; the energy it will end up saving in the home over its' lifetime far surpasses the amount needed to make it.

Finally, the adhesives used to secure the OSB board to the EPS foam is water-based; there are no solvents or VOC emissions to compromise indoor air quality.

PorterSIPs: Efficient Construction

Let's summarize: PorterSIPs are manufactured in the U.S. with environmentally beneficial and sustainable materials. They create an air-tight, extremely energy-efficient structure that saves not only money but money over time.

In addition to these green attributes, PorterSIPs also benefit the construction process itself. They are made in an environmentally-controlled factory facility; this allows for extremely accurate manufacturing to exacting standards. The entire manufacturing process is monitored by full-time quality inspectors, and the entire facility is audited by a 3rd party inspection agency.

This precision manufacturing in a controlled environment is much more accurate than constructing a stick-built frame on the building site. It also reduces costs by reducing the amount of labor and time necessary to install the SIPs on-site. A recent study by BASF found a 55% reduction in construction labor (and its associated labor cost) through the use of SIPs.

A precision-manufactured SIP product also dramatically reduces construction waste, which can often send trucks full of framing waste to the landfill.

Here at Green Home Source, we're hard-pressed to find any negatives regarding PorterSIPs: a locally-manufactured product providing much-needed jobs in a down economy, using sustainable techniques and materials to create a strong, efficient building material that will save homeowners energy and money savings for the life of their home.

For more information on Structural Insulated Panels, read our article on the subject here.